Help Us Out

We’re looking for customers to test this new WinDaq software approach for defining engineering units and give us their opinions. Currently the new code is available only for starter kits, so anyone with a DI-194(RS), -154RS, -148U, -148U-SP, -158U, -158UP, -145, -149, or DI-155 qualifies. To sign up, please leave a comment on this blog post with a valid email address, and we’ll follow up with instructions. Note that the new code doesn’t yet replace the other engineering unit scaling options. So, if you hate the new approach you have time to tell us why and have us fix it before it does. Finally, we’ve tested this code and found it to work well, so we hope your evaluation applies only to look and feel. Of course, if you trip on a bug please let us know.

What follows should give you a good feel for why we’re making this change and why its better. Of course, feel free to post any questions you may have in the comments section.

Engineering Unit Scaling Background

The first thing that most data acquisition and data logger equipment users want to do after they acquire analog data is to scale it into meaningful units. To most, acquired data displayed in volts is next to meaningless. They need the ability to translate volts into meaningful measures, like PSI, Newtons, ft-lb, mmHg, etc. These are often referred to as engineering units (EU), and the process of converting voltages applied to the input into meaningful measures like these is referred to as engineering unit scaling. Of course, DATAQ Instruments’ popular WinDaq application supports this feature, but you’ve let us know that the procedure, as well as what we call it, needs improvement.

You talked. We listened.

We heard you. Based upon countless conversations with you, it was clear that our current High/Low method as well as the Fixed method of converting to engineering units was neither intuitive nor easy to use. We also sensed that we confused our customer base through our use of the word calibration to refer to EU scaling. Many customers rightfully feared that they would change the actual calibration of the data acquisition unit if they used these features. None of this is good news for a feature that is so crucial to data acquisition and data logging operations.

A New Engineering Unit Scaling Dialog Box

We’ve responded with a fresh approach to engineering unit scaling that we hope you will view as a major step forward for WinDaq ease-of-use.

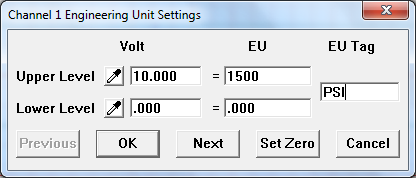

Nearby you will see a graphic image of our new Engineering Unit Settings dialog box, which will eventually replace our current High/Low and Fixed dilaog box approaches. I hope at first glance that, aside from minor questions, it’s obvious how to use it. In the most basic applications, you know the relationship of volts to engineering units and you simply define that relationship using the supplied dialog boxes. Some examples:

- 10V equals 500 PSI and 0V equals zero PSI.

- Under the Volt column, you’d set Upper Level equal to “10” and Lower Level equal to “0”

- Under the EU column, you’d set Upper Level equal to “500” and Lower Level equal to “0”

- Set the EU Tag dialog box to “PSI”

- Done!

- Using a 250-Ohm resistor on a process current loop where the sensor’s output is 300 lbs at 20 mA and 0 lbs at 4 ma

- Since the 250-Ohm resistor converts the 4-20 mA signal to 1-5 V…

- Under the Volt column, you’d set Upper Level equal to “5” and Lower Level equal to “1”

- Under the EU column, you’d set Upper Level equal to “300” and Lower Level equal to “0”

- Set the EU Tag dialog box to “LBS”

- Done!

Some Additional Features

As you study the new Engineering Units Settings dialog box you’ll notice some interesting items starting with the eyedropper icons adjacent to the Volt data entry boxes.

We’ve noticed that many WinDaq users simply do not know the relationship of volts output from the sensor versus engineering units, so they derive the relationship empirically. Using the example of a load cell with an unknown output versus pounds of applied force, they’ll apply no load, then measure and record the voltage output. Then they’ll measure and record the output with a known load applied. The two recorded voltage values versus applied load can be entered in the appropriate boxes to define the relationship.

The eyedroppers eliminate a couple steps. They allow you to sample the current value of the applied voltage when you click the icon, and have it automatically displayed in the Volt box for either the Upper or Lower value depending upon the applied load. Continuing with the example, you’d apply no load and click the Lower eyedropper so the software will acquire the lower voltage value and display it automatically in the Lower box for voltage. Then you’d enter zero for the lower EU value. Next, you’d apply your known load and do the same for the Upper values. Enter your EU Tag and you’re done. As you can see for this calibration method, using the eyedroppers saves time and greatly reduces the possibility of human error.

Finally, there’s the Set Zero button that allows you to instantly compensate for zero offsets from your measurement. How many times have you carefully calibrated a system only to see a slight offset in the result when you apply zero engineering units? It’s very common. You can apply zero engineering units to your sensor and then use the Set Zero feature to instantly force the offset to zero when you click the button.

Help Facility

In the final version that we release to everyone, an additional button labeled Help (not available in this beta version) will provide a dedicated help reference just for the Engineering Unit Settings dialog box.

View Cart

View Cart sales@dataq.com

sales@dataq.com 330-668-1444

330-668-1444

25 Comments

George Bynum

The “Set Zero” could use more thought. I’ll give a real world example I see regularly.

Using a device that gives a “volts/inch” response, I can “calibrate” or set EU relatively easily … either empirically via a standard of some sort (may be a dial indicator or tape measure type thing depending on range). When I fix it to my “DUT”, often with a c-clamp, magnet, or vise-grip type pliers, I might then move the axis to home or use ANOTHER KNOWN POSITION and want to set the appropriate offset. I’d like, for example, to be able to enter somehow that present position is something … USUALLY zero, but not always.

Real example … a machine has a clamp which never quite gets to zero, but with an HMI giving present position. I’d like to sync my acquisition to the HMI value.

So … another entry box, defaulting to probably zero, but perhaps present calculated position after setting EU scale, with the set zero button labelled SetHere or SetPresent or something.

DaqGuy

George,

Good points. We got fixated on zero and never thought about the possibility of non-zero offsets.

So, in your view, if we changed the “Set Zero” button to “Set Offset” with an EU dialog box containing a default value of zero, but allowing other entries between ±EU full scale, that would work?

I’d like to handle it this way as opposed to adding another button. More options add complexity, and complexity breeds confusion.

Assuming that I’m properly tracking your recommendation, we will attempt to make the change. Right now, we don’t see any reason why it cannot operate in the described manner, but we may revert if unanticipated obstacles are encountered.

Thank you for sharing your ideas.

George Bynum

That would work fine; without giving 100% thought, I might label the button “Set Present To:” rather than use the term offset …

Brett

Hi. I’ve been using a DI-194RS for a couple of years now to monitor the power output from my wind generator and solar panels. The new layout looks far more intuitive to set up. I’d reconfigured how I was measuring the individual amperages and voltages a few times and it had always been a little confusing and prone to human error…

I’m a mechanic and also use a 194 with a laptop in the workshop to test outputs of engine management sensors… this new setup should simplify that too.

Good work team!

Dr. Howard Rogers

I am interested in trying your new beta software. I have a -148U.

310-532-3342

Bob Reinstatler

I’m a retired engineering tech, and I still greatly enjoy tinkering using my DI-194RS, DI-154RS (the 154RS is dedicated to my home-built seismograph), and DI-158U. The New Engineering Units Settings diaglog looks like a good improvement over the present method and I’d be happy to give it a try.

Bob

Tony Stewart

It looks like a good approach. I’d like to try it with my DI-148U

Thanks

Tony

Terry Lee

I have had a DI-158 for a couple of years – great little piece of equipment, my compliments – the current SW is, as you say, not real straight forward and mildly cumbersome – would love to try the new software

Ben Russell

I’d like to give the beta version a try.

Lindsay Ambler

We are working through a series of new calibrations right now. Would love to try the new software. Thanks!

Pablo Calcerrada

I am using a DI 149 and i`d like to try the beta version.

Jeff Maslin

I monitor the (Earth’s) local magnetic field nearly 24/7 using the 148.I also have 2 145’s that I use in a wide variety of data collection of magnetic and electrical fields around the human body. There are several other uses I have for my data loggers, but these are the most frequently used.

I’d like to try the new version as much of my use requires calibration of different units such as (but not limited to) Gauss.

DaqGuy

Thanks for your comments. We’re currently working on a version that incorporates offsets other than zero, which will take a few days to code and test. After that we’ll contact each of you by email with instructions on how to download and install the new version. The plan is to have both data acquisition and playback versions ready.

I’ll keep you appraised.

Thomas Harvey

I would like to try the beta version with my DI-145 that I use with a load cell.

Michael Smith

I have a DI-145. The new calibration with “offsets” looks to be more intuitive.

I would like to try the new version.

Thanks,

Mike

Jim

I’ve been using a DI-148U for over a year, usually measuring voltage. However, on several occasions I was measuring G’s using an accelerometer. This new format would have encouraged me to let the program do the conversion rather than dumping the data to an Excel spreadsheet and manipulating the data there. A beta version to try would be great.

Richard

I’ve been using a DI-148U for the last 12 months monitoring room temperatures in my home, prior to installing additional insulation – about to happen. I had some trouble setting up the calibration – mostly my fault I think, and have been relying on adjusting and correcting the data in Excel spreadsheets afterwards. The new dialogue settings method appears to be so much more intuitive……………. I’d definitely like to trial the new beta software. Thanks.

Sherwin Roy

I have a DI-194 and DI-148 and Di-158u.

I would be interested in trying the beta version

Thank you,

Sherwin Roy

Jeff Heinzen

I have Di-158.

I would be interested in trying the beta version

Thank you,

Andy

Like Jeff.

Beta still available?

Sherwin Roy

I have a DI-194RS, DI-148U, and DI-158U

I would be interested in trying the new calibration method.

Thank you,

Sherwin Roy

Allan Pinkul

I have been using Dataq instruments since 1995.

I currently have a DI-158U, DI-145, DI-194RS.

The “Low” Cal point has to be set first which defines the low end of the scale. Next set the “High” Cal point which sets the slope of the curve. Then go to File, Save Default Value. (these values are not actually saved until you close the program) Restart the program and enter a new “lo-Cal” value to correct the offset which shifts the whole slope of the curve up or down without changing the calibration, you are just correcting the calibration. Then go to “File”, Save Default Value. Close then re-start the program and the values will be permanently saved.

It’s important to know the process.

I don’t see where you tell the users to always do Low Cal first and the reasons why.

Al pinkul

Bill Goodwin

We have a number of DI-155’s and a lot of the guy’s do get hung up on the scaling and calibration. i would like to give thebeta version a test run.

Thanks,

Bill

Robert Bethman

I’d welcome getting involved! I just procured a DI-194RS with software, cable and disc. Will be using it to monitor a Home Made GPSDO. A constant track of status and changes is highly desired. A.R.S. N0DGN, 67yr. old Veteran

DaqGuy

Thanks, but we wrapped this up years ago. Likewise, the DI-194RS has been obsolete for many years, but you can download the last available software here:

https://www.dataq.com/support/upgrades/record/g6level2.html

Note that this software does not support the EU dialogs discussed in this post, since the instrument was obsolete long before they were implemented.