The question comes up often, “Can I connect a thermocouple to your data acquisition system and a secondary device (i.e. additional monitoring equipment, a controller, etc), at the same time?” The answer is yes. It’s often convenient to make a parallel measurement when using a thermocouple to acquire temperature data, while using the same temperature information to control a process. There are some caveats however.

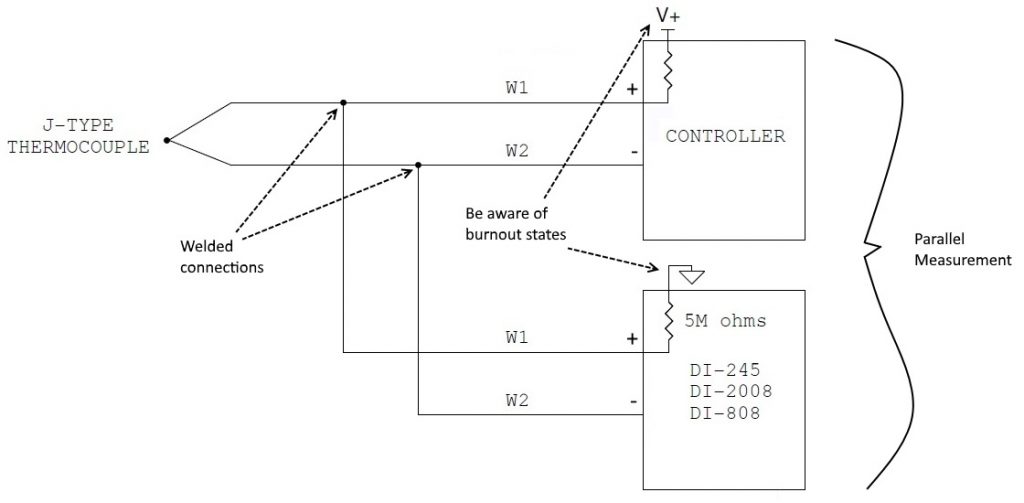

To start with, the wires used to attach the thermocouple to both the data acquisition instrument and the secondary device, must be made of the same metal/alloy (as appropriate for the thermocouple type being used). In the case of a J-type thermocouple for example, the positive (white) wire is made of Iron and the negative (red) wire is made of Constantan, an alloy comprised of copper and nickel. In addition to using like-wires, the wire-to-wire connections should be welded, not simply twisted together. A loose junction can produce inconsistent temperature readings.

Another consideration when connecting a single thermocouple to two devices, is how those devises convey a burnout conditions. In our example, DI-245, DI-2008 and DI-808 series instruments all pull the positive input low using a 5 MΩ resistor. Assuming that the secondary device pulls the input high in the event of a burnout, the data acquisition device would never recognize the burnout condition. You could still make the temperature measurement under normal circumstances however.

Additional Reading:

Be Mindful of Polarity When Making Thermocouple Measurements

View Cart

View Cart sales@dataq.com

sales@dataq.com 330-668-1444

330-668-1444

One Comment

Ray Peacock

Nice note! we’ll add a note about it with a link on TempSensorNEWS.com.